Tool And Die Maker Resume Examples and Templates

This page provides you with Tool And Die Maker resume samples to use to create your own resume with our easy-to-use resume builder. Below you'll find our how-to section that will guide you through each section of a Tool And Die Maker resume.

What Do Hiring Managers Look for in a Tool And Die Maker Resume

- Precision machining skills for accurate fabrication.

- Blueprint interpretation to understand design requirements.

- Construction and repair of tools, dies, jigs, and fixtures.

- Proficiency in CNC programming and operation.

- Quality assurance through meticulous inspection and measurement.

How to Write a Tool And Die Maker Resume?

To write a professional Tool And Die Maker resume, follow these steps:

- Select the right Tool And Die Maker resume template.

- Write a professional summary at the top explaining your Tool And Die Maker’s experience and achievements.

- Follow the STAR method while writing your Tool And Die Maker resume’s work experience. Show what you were responsible for and what you achieved as a Tool And Die Maker.

- List your top Tool And Die Maker skills in a separate skills section.

How to Write Your Tool And Die Maker Resume Header?

Write the perfect Tool And Die Maker resume header by:

- Adding your full name at the top of the header.

- Add a photo to your resume if you are applying for jobs outside of the US. For applying to jobs within the US, avoid adding photo to your resume header.

- Add your current Tool And Die Maker job title to the header to show relevance.

- Add your current city, your phone number and a professional email address.

- Finally, add a link to your portfolio to the Tool And Die Maker resume header. If there’s no portfolio link to add, consider adding a link to your LinkedIn profile instead.

Bad Tool And Die Maker Resume Example - Header Section

Aisha 696 Rock Maple St. South Lyon, MI 48178 Marital Status: Married, email: cooldude2022@gmail.com

Good Tool And Die Maker Resume Example - Header Section

Aisha Oneill, Lyon, MI, Phone number: +1-555-555-5555, Link: linkedin/in/johndoe

Make sure to add a professional looking email address while writing your resume header. Let’s assume your name is John Doe - here is a formula you can use to create email addresses:

- firstnamelastname@email.com - johndoe@email.com

- firstname.lastname@email.com - john.doe@email.com

- lastname.firstname@email.com - doe.john@email.com

- f.lastname@email.com - j.doe@email.com

- l.firstname@email.com - d.john@email.com

- firstnamelastname12@email.com - johndoe12@email.com

For a Tool And Die Maker email, we recommend you either go with a custom domain name (john@johndoe.com) or select a very reputed email provider (Gmail or Outlook).

How to Write a Professional Tool And Die Maker Resume Summary?

Use this template to write the best Tool And Die Maker resume summary: Tool And Die Maker with [number of years] experience of [top 2-3 skills]. Achieved [top achievement]. Expert at [X], [Y] and [Z].

How to Write a Tool And Die Maker Resume Experience Section?

Here’s how you can write a job winning Tool And Die Maker resume experience section:

- Write your Tool And Die Maker work experience in a reverse chronological order.

- Use bullets instead of paragraphs to explain your Tool And Die Maker work experience.

- While describing your work experience focus on highlighting what you did and the impact you made (you can use numbers to describe your success as a Tool And Die Maker).

- Use action verbs in your bullet points.

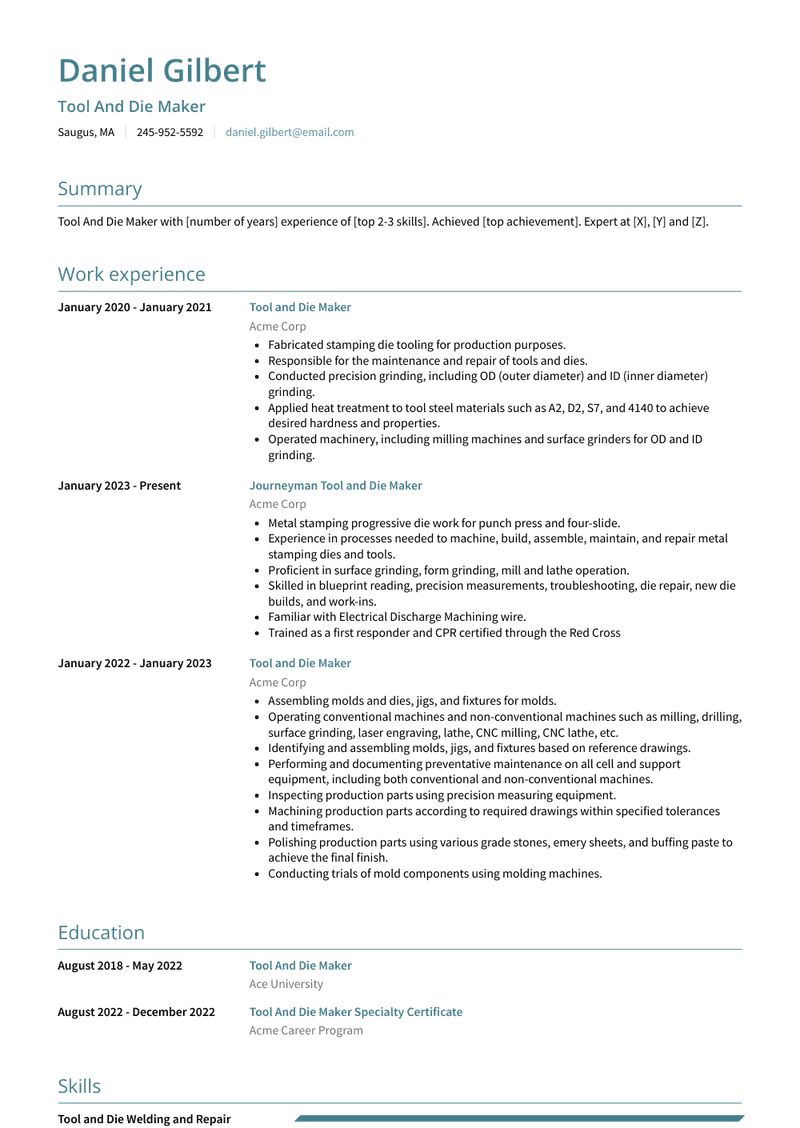

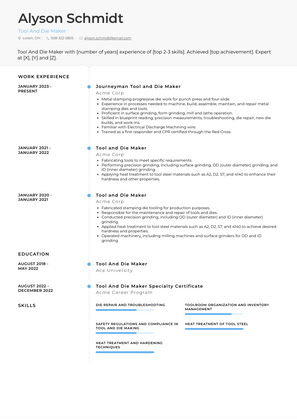

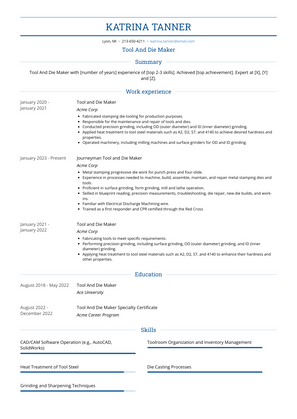

Journeyman Tool and Die Maker Resume Example

Journeyman Tool and Die Maker

- Metal stamping progressive die work for punch press and four-slide.

- Experience in processes needed to machine, build, assemble, maintain, and repair metal stamping dies and tools.

- Proficient in surface grinding, form grinding, mill and lathe operation.

- Skilled in blueprint reading, precision measurements, troubleshooting, die repair, new die builds, and work-ins.

- Familiar with Electrical Discharge Machining wire.

- Trained as a first responder and CPR certified through the Red Cross

Tool and Die Maker Resume Example

Tool and Die Maker

- Assembling molds and dies, jigs, and fixtures for molds.

- Operating conventional machines and non-conventional machines such as milling, drilling, surface grinding, laser engraving, lathe, CNC milling, CNC lathe, etc.

- Identifying and assembling molds, jigs, and fixtures based on reference drawings.

- Performing and documenting preventative maintenance on all cell and support equipment, including both conventional and non-conventional machines.

- Inspecting production parts using precision measuring equipment.

- Machining production parts according to required drawings within specified tolerances and timeframes.

- Polishing production parts using various grade stones, emery sheets, and buffing paste to achieve the final finish.

- Conducting trials of mold components using molding machines.

Tool and Die Maker Resume Example

Tool and Die Maker

- Fabricating tools to meet specific requirements.

- Performing precision grinding, including surface grinding, OD (outer diameter) grinding, and ID (inner diameter) grinding.

- Applying heat treatment to tool steel materials such as A2, D2, S7, and 4140 to enhance their hardness and other properties.

Tool and Die Maker Resume Example

Tool and Die Maker

- Fabricated stamping die tooling for production purposes.

- Responsible for the maintenance and repair of tools and dies.

- Conducted precision grinding, including OD (outer diameter) and ID (inner diameter) grinding.

- Applied heat treatment to tool steel materials such as A2, D2, S7, and 4140 to achieve desired hardness and properties.

- Operated machinery, including milling machines and surface grinders for OD and ID grinding.

Top Tool And Die Maker Resume Skills for 2023

- Blueprint Reading and Interpretation

- Precision Machining and Toolmaking

- CAD/CAM Software Operation (e.g., AutoCAD, SolidWorks)

- CNC Programming and Operation

- Manual Milling and Lathe Operation

- Grinding and Sharpening Techniques

- Heat Treatment of Tool Steel

- Precision Measurement and Inspection

- Tool Design and Development

- Die Design and Development

- Jig and Fixture Design

- Surface Finishing Techniques

- Tool and Die Maintenance and Repair

- Metal Stamping and Forming Techniques

- EDM (Electrical Discharge Machining) Operation

- Wire EDM Operation

- Precision Grinding (Surface, Cylindrical, Tool & Cutter)

- Welding and Brazing Techniques

- CNC Wire Cutting

- CNC Sinker and EDM Drilling

- Heat Treatment and Hardening Techniques

- Metalworking Machinery Operation (e.g., press brakes, shears)

- CNC Programming and Troubleshooting

- Tool Material Selection and Machinability

- Metrology and Measurement Tools (e.g., micrometers, calipers)

- Tolerances and Fits

- Computer-Aided Inspection (CAI)

- Reverse Engineering Techniques

- CAM (Computer-Aided Manufacturing) Programming

- Tooling Documentation and Technical Drawings

- Die Casting Processes

- Press Tooling Design and Development

- Progressive Die Design

- Punch and Die Maintenance

- Tooling Assembly and Set-Up

- Toolroom Organization and Inventory Management

- Safety Practices in Tool and Die Making

- Project Management for Tool and Die Projects

- Die Repair and Troubleshooting

- Tool and Die Welding and Repair Techniques

- Tooling Preventive Maintenance

- Quality Control and Inspection Techniques

- Problem-Solving and Root Cause Analysis

- CNC Wire EDM Programming

- CAD/CAM Simulation and Verification

- Safety Regulations and Compliance in Tool and Die Making

- Tool and Die Cost Estimation and Budgeting

How Long Should my Tool And Die Maker Resume be?

Your Tool And Die Maker resume length should be less than one or two pages maximum. Unless you have more than 25 years of experience, any resume that’s more than two pages would appear to be too long and risk getting rejected.

On an average, for Tool And Die Maker, we see most resumes have a length of 2. And, that’s why we advise you to keep the resume length appropriate to not get rejected.

Copyright ©2025 Workstory Inc.