Metal Fabricator Resume Examples and Templates

This page provides you with Metal Fabricator resume samples to use to create your own resume with our easy-to-use resume builder. Below you'll find our how-to section that will guide you through each section of a Metal Fabricator resume.

What do Hiring Managers look for in a Metal Fabricator Resume

- Technical Skills: Proficiency in metalworking techniques such as cutting, bending, welding, and shaping metal to fabricate components and structures.

- Attention to Detail: Precision and accuracy in interpreting blueprints, specifications, and technical drawings to ensure finished products meet quality standards.

- Problem-Solving Abilities: Capability to identify and troubleshoot issues during the fabrication process, finding creative solutions to overcome challenges and achieve desired outcomes.

- Safety Consciousness: Commitment to adhering to safety protocols and procedures, including proper use of protective equipment and safe operation of machinery to prevent accidents and injuries.

- Teamwork: Collaboration with colleagues, engineers, and project managers to coordinate fabrication projects, share expertise, and ensure project goals are met efficiently.

How to Write a Metal Fabricator Resume?

To write a professional Metal Fabricator resume, follow these steps:

- Select the right Metal Fabricator resume template.

- Write a professional summary at the top explaining your Metal Fabricator’s experience and achievements.

- Follow the STAR method while writing your Metal Fabricator resume’s work experience. Show what you were responsible for and what you achieved as a Metal Fabricator.

- List your top Metal Fabricator skills in a separate skills section.

How to Write Your Metal Fabricator Resume Header?

Write the perfect Metal Fabricator resume header by:

- Adding your full name at the top of the header.

- Add a photo to your resume if you are applying for jobs outside of the US. For applying to jobs within the US, avoid adding photo to your resume header.

- Add your current Metal Fabrication position to the header to show relevance.

- Add your current city, your phone number and a professional email address.

- Finally, add a link to your portfolio to the Metal Fabricator resume header. If there’s no portfolio link to add, consider adding a link to your LinkedIn profile instead.

Bad Metal Fabricator Resume Example - Header Section

Taylor 35 Marshall Drive Chardon, OH 44024 Marital Status: Married, email: cooldude2022@gmail.com

Good Metal Fabricator Resume Example - Header Section

Taylor Malone, Chardon, OH, Phone number: +1-555-555-5555, Link: linkedin/in/johndoe

Make sure to add a professional looking email address while writing your resume header. Let’s assume your name is John Doe - here is a formula you can use to create email addresses:

- firstnamelastname@email.com - johndoe@email.com

- firstname.lastname@email.com - john.doe@email.com

- lastname.firstname@email.com - doe.john@email.com

- f.lastname@email.com - j.doe@email.com

- l.firstname@email.com - d.john@email.com

- firstnamelastname12@email.com - johndoe12@email.com

For a Metal Fabricator email, we recommend you either go with a custom domain name (john@johndoe.com) or select a very reputed email provider (Gmail or Outlook).

How to Write a Professional Metal Fabricator Resume Summary?

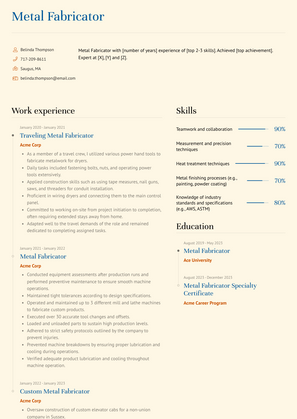

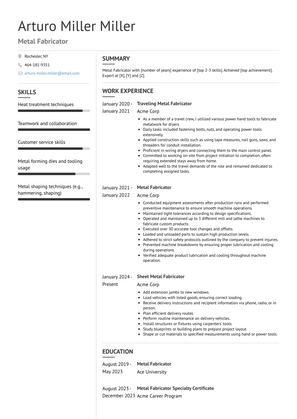

Use this template to write the best Metal Fabricator resume summary: Metal Fabricator with [number of years] experience of [top 2-3 skills]. Achieved [top achievement]. Expert at [X], [Y] and [Z].

How to Write a Metal Fabricator Resume Experience Section?

Here’s how you can write a job winning Metal Fabricator resume experience section:

- Write your Metal Fabricator work experience in a reverse chronological order.

- Use bullets instead of paragraphs to explain your Metal Fabricator work experience.

- While describing your work experience focus on highlighting what you did and the impact you made (you can use numbers to describe your success as a Metal Fabricator).

- Use action verbs in your bullet points.

Sheet Metal Fabricator Resume Example

Sheet Metal Fabricator

- Add extension jambs to new windows.

- Load vehicles with listed goods, ensuring correct loading.

- Receive delivery instructions and recipient information via phone, radio, or in person.

- Plan efficient delivery routes.

- Perform routine maintenance on delivery vehicles.

- Install structures or fixtures using carpenters' tools.

- Study blueprints or building plans to prepare project layout.

- Shape or cut materials to specified measurements using hand or power tools.

Custom Metal Fabricator Resume Example

Custom Metal Fabricator

- Fabricated custom metal parts for elevator systems in a non-union company.

- Operated shearing and hydraulic press break machines.

- Utilized computer-based laser cutting/etching machines.

- Conducted MIG and TIG welding on stainless steel and cold rolled steel.

- Performed finishing tasks using handheld tools like grinders and cutting wheels.

- Promoted to manage a new branch of the metal shop within 9 months.

- Obtained OSHA forklift safety certification within the first month of employment.

Custom Metal Fabricator Resume Example

Custom Metal Fabricator

- Oversaw construction of custom elevator cabs for a non-union company in Sussex.

- Specialized in materials like textured & colored glass, fine woods, laminate veneers, textured stainless steel, and woven metals.

- Conducted site visits and utilized CAD program for drafting and designing custom cabs.

- Fabricated interiors for the AMX building.

- Constructed front claddings, ceilings, and doors for a significant renovation project.

Metal Fabricator Resume Example

Metal Fabricator

- Conducted equipment assessments after production runs and performed preventive maintenance to ensure smooth machine operations.

- Maintained tight tolerances according to design specifications.

- Operated and maintained up to 3 different mill and lathe machines to fabricate custom products.

- Executed over 30 accurate tool changes and offsets.

- Loaded and unloaded parts to sustain high production levels.

- Adhered to strict safety protocols outlined by the company to prevent injuries.

- Prevented machine breakdowns by ensuring proper lubrication and cooling during operations.

- Verified adequate product lubrication and cooling throughout machine operation.

Traveling Metal Fabricator Resume Example

Traveling Metal Fabricator

- As a member of a travel crew, I utilized various power hand tools to fabricate metalwork for dryers.

- Daily tasks included fastening bolts, nuts, and operating power tools extensively.

- Applied construction skills such as using tape measures, nail guns, saws, and threaders for conduit installation.

- Proficient in wiring dryers and connecting them to the main control panel.

- Committed to working on-site from project initiation to completion, often requiring extended stays away from home.

- Adapted well to the travel demands of the role and remained dedicated to completing assigned tasks.

Top Metal Fabricator Resume Skills for 2023

- Reading and interpreting blueprints, drawings, and specifications

- Metal cutting techniques (e.g., sawing, shearing, plasma cutting)

- Metal forming techniques (e.g., bending, rolling, stamping)

- Welding processes (e.g., MIG, TIG, stick welding)

- Brazing and soldering techniques

- Metal joining techniques (e.g., riveting, bolting)

- Metal finishing techniques (e.g., grinding, sanding, polishing)

- Metal shaping techniques (e.g., hammering, shaping)

- Layout and marking out

- Metal fabrication equipment operation (e.g., press brakes, punch presses)

- CNC machining operation

- Metal drilling and tapping

- Sheet metal fabrication techniques

- Tube bending and fabrication

- Metal casting techniques

- Metal fabrication tool usage (e.g., grinders, drills, bandsaws)

- Measurement and precision techniques

- Material handling and lifting

- Safety protocols adherence

- Personal protective equipment (PPE) usage

- Understanding of metallurgy principles

- Knowledge of different metal types and their properties

- Heat treatment techniques

- Metal forming dies and tooling usage

- CNC programming and operation

- Metal assembly techniques

- Metal finishing processes (e.g., painting, powder coating)

- Quality control and inspection techniques

- Root cause analysis for fabrication defects

- Problem-solving skills

- Decision-making skills

- Time management

- Attention to detail

- Communication skills (verbal and written)

- Teamwork and collaboration

- Adaptability to changing project requirements

- Project management skills

- Budget management for materials and resources

- Environmental and regulatory compliance

- Continuous learning and professional development in metal fabrication techniques

- CAD/CAM software proficiency

- Blueprint creation and modification

- Knowledge of industry standards and specifications (e.g., AWS, ASTM)

- Documentation and record-keeping

- Customer service skills

- Vendor management

- Inventory management

- Cost estimation and bidding

- Environmental sustainability practices

- Workplace organization and cleanliness

How Long Should my Metal Fabricator Resume be?

Your Metal Fabricator resume length should be less than one or two pages maximum. Unless you have more than 25 years of experience, any resume that’s more than two pages would appear to be too long and risk getting rejected.

On an average, for Metal Fabricator, we see most resumes have a length of 2. And, that’s why we advise you to keep the resume length appropriate to not get rejected.

Copyright ©2025 Workstory Inc.