Manufacturing Engineer Resume Examples and Templates

This page provides you with Manufacturing Engineer resume samples to use to create your own resume with our easy-to-use resume builder. Below you'll find our how-to section that will guide you through each section of a Manufacturing Engineer resume.

What do Hiring Managers look for in a Manufacturing Engineer Resume

- Technical Proficiency: Strong engineering knowledge and skills related to manufacturing processes, materials, and equipment.

- Problem-Solving Skills: Capability to identify and address manufacturing challenges, optimize processes, and improve product quality and efficiency.

- Process Improvement: Experience in continuous process improvement methodologies like Lean Six Sigma or Kaizen to enhance manufacturing operations.

- Design and Innovation: Ability to collaborate with product designers and engineers to ensure manufacturability and cost-effectiveness.

- Project Management: Proficiency in managing manufacturing projects, budgets, and resources to meet production goals and timelines.

How to Write a Manufacturing Engineer Resume?

To write a professional Manufacturing Engineer resume, follow these steps:

- Select the right Manufacturing Engineer resume template.

- Write a professional summary at the top explaining your Manufacturing Engineer’s experience and achievements.

- Follow the STAR method while writing your Manufacturing Engineer resume’s work experience. Show what you were responsible for and what you achieved as a Manufacturing Engineer.

- List your top Manufacturing Engineer skills in a separate skills section.

How to Write Your Manufacturing Engineer Resume Header?

Write the perfect Manufacturing Engineer resume header by:

- Adding your full name at the top of the header.

- Add a photo to your resume if you are applying for jobs outside of the US. For applying to jobs within the US, avoid adding photo to your resume header.

- Add your current Manufacturing Engineering position to the header to show relevance.

- Add your current city, your phone number and a professional email address.

- Finally, add a link to your portfolio to the Manufacturing Engineer resume header. If there’s no portfolio link to add, consider adding a link to your LinkedIn profile instead.

Bad Manufacturing Engineer Resume Example - Header Section

Araceli 7600 W. Bay Meadows Avenue Rochester, NY 14606 Marital Status: Married, email: cooldude2022@gmail.com

Good Manufacturing Engineer Resume Example - Header Section

Araceli Duarte, Rochester, NY, Phone number: +1-555-555-5555, Link: linkedin/in/johndoe

Make sure to add a professional looking email address while writing your resume header. Let’s assume your name is John Doe - here is a formula you can use to create email addresses:

- firstnamelastname@email.com - johndoe@email.com

- firstname.lastname@email.com - john.doe@email.com

- lastname.firstname@email.com - doe.john@email.com

- f.lastname@email.com - j.doe@email.com

- l.firstname@email.com - d.john@email.com

- firstnamelastname12@email.com - johndoe12@email.com

For a Manufacturing Engineer email, we recommend you either go with a custom domain name (john@johndoe.com) or select a very reputed email provider (Gmail or Outlook).

How to Write a Professional Manufacturing Engineer Resume Summary?

Use this template to write the best Manufacturing Engineer resume summary: Manufacturing Engineer with [number of years] experience of [top 2-3 skills]. Achieved [top achievement]. Expert at [X], [Y] and [Z].

How to Write a Manufacturing Engineer Resume Experience Section?

Here’s how you can write a job winning Manufacturing Engineer resume experience section:

- Write your Manufacturing Engineer work experience in a reverse chronological order.

- Use bullets instead of paragraphs to explain your Manufacturing Engineer work experience.

- While describing your work experience focus on highlighting what you did and the impact you made (you can use numbers to describe your success as a Manufacturing Engineer).

- Use action verbs in your bullet points.

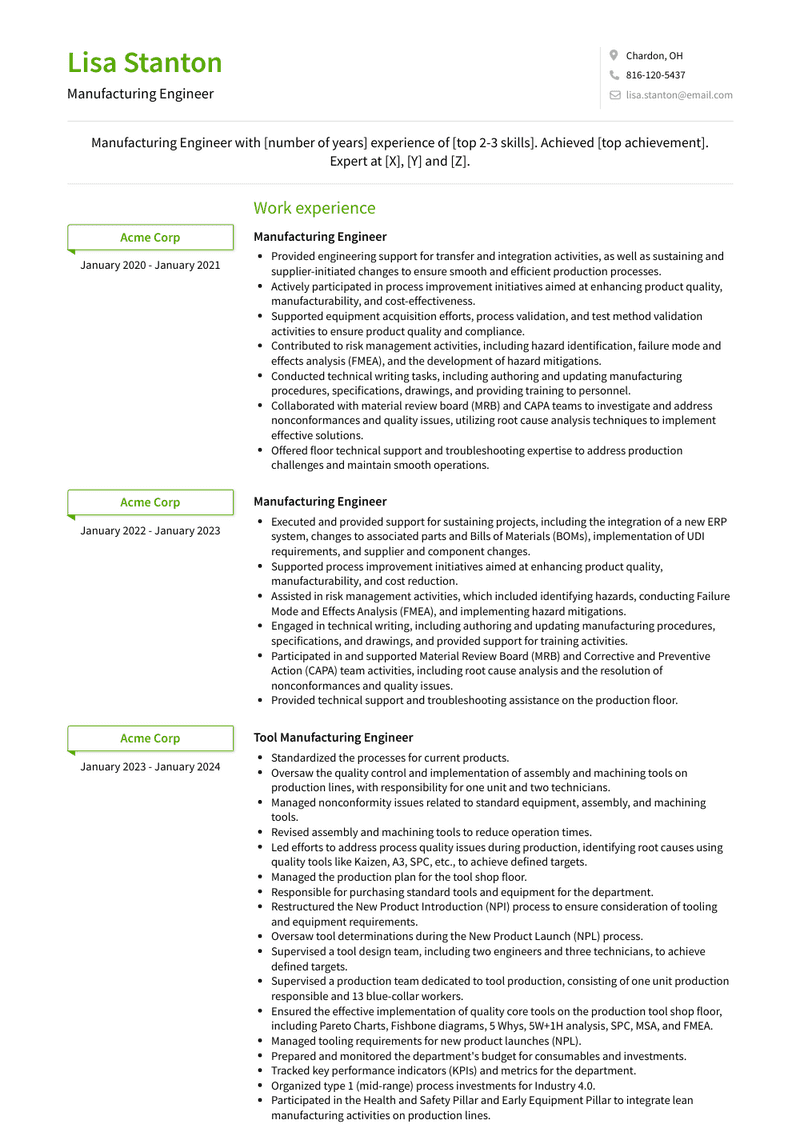

Manufacturing Engineer Resume Example

Manufacturing Engineer

- Managed the rework process of PCBs with BGA chips using a Vapor Phase Reflow Machine.

- Assisted the Project Manager in ensuring that the rework process met the weekly shipment targets set by the customer.

- Engaged in customer meetings to verify that the rework process and product quality aligned with customer requirements.

- Worked in collaboration with the SMT programmer to develop new programs or make modifications to existing programs for the PCB process.

Tool Manufacturing Engineer Resume Example

Tool Manufacturing Engineer

- Standardized the processes for current products.

- Oversaw the quality control and implementation of assembly and machining tools on production lines, with responsibility for one unit and two technicians.

- Managed nonconformity issues related to standard equipment, assembly, and machining tools.

- Revised assembly and machining tools to reduce operation times.

- Led efforts to address process quality issues during production, identifying root causes using quality tools like Kaizen, A3, SPC, etc., to achieve defined targets.

- Managed the production plan for the tool shop floor.

- Responsible for purchasing standard tools and equipment for the department.

- Restructured the New Product Introduction (NPI) process to ensure consideration of tooling and equipment requirements.

- Oversaw tool determinations during the New Product Launch (NPL) process.

- Supervised a tool design team, including two engineers and three technicians, to achieve defined targets.

- Supervised a production team dedicated to tool production, consisting of one unit production responsible and 13 blue-collar workers.

- Ensured the effective implementation of quality core tools on the production tool shop floor, including Pareto Charts, Fishbone diagrams, 5 Whys, 5W+1H analysis, SPC, MSA, and FMEA.

- Managed tooling requirements for new product launches (NPL).

- Prepared and monitored the department's budget for consumables and investments.

- Tracked key performance indicators (KPIs) and metrics for the department.

- Organized type 1 (mid-range) process investments for Industry 4.0.

- Participated in the Health and Safety Pillar and Early Equipment Pillar to integrate lean manufacturing activities on production lines.

Manufacturing Engineer Resume Example

Manufacturing Engineer

- Executed and provided support for sustaining projects, including the integration of a new ERP system, changes to associated parts and Bills of Materials (BOMs), implementation of UDI requirements, and supplier and component changes.

- Supported process improvement initiatives aimed at enhancing product quality, manufacturability, and cost reduction.

- Assisted in risk management activities, which included identifying hazards, conducting Failure Mode and Effects Analysis (FMEA), and implementing hazard mitigations.

- Engaged in technical writing, including authoring and updating manufacturing procedures, specifications, and drawings, and provided support for training activities.

- Participated in and supported Material Review Board (MRB) and Corrective and Preventive Action (CAPA) team activities, including root cause analysis and the resolution of nonconformances and quality issues.

- Provided technical support and troubleshooting assistance on the production floor.

Manufacturing Engineer Resume Example

Manufacturing Engineer

- Held responsibility for overseeing the daily production activities of material receiving and manufacturing operations.

- Developed a floor layout plan that resulted in a 25% reduction in floor space usage, optimizing the production environment.

- Provided ongoing support for troubleshooting and resolving product or process issues on the manufacturing floor.

- Implemented lean manufacturing principles and tools to eliminate non-value-added waste from various processes, leading to increased productivity.

- Investigated and addressed various Customer Quality Concerns by identifying root causes and implementing effective countermeasures to improve product quality and customer satisfaction.

Manufacturing Engineer Resume Example

Manufacturing Engineer

- Provided engineering support for transfer and integration activities, as well as sustaining and supplier-initiated changes to ensure smooth and efficient production processes.

- Actively participated in process improvement initiatives aimed at enhancing product quality, manufacturability, and cost-effectiveness.

- Supported equipment acquisition efforts, process validation, and test method validation activities to ensure product quality and compliance.

- Contributed to risk management activities, including hazard identification, failure mode and effects analysis (FMEA), and the development of hazard mitigations.

- Conducted technical writing tasks, including authoring and updating manufacturing procedures, specifications, drawings, and providing training to personnel.

- Collaborated with material review board (MRB) and CAPA teams to investigate and address nonconformances and quality issues, utilizing root cause analysis techniques to implement effective solutions.

- Offered floor technical support and troubleshooting expertise to address production challenges and maintain smooth operations.

Top Manufacturing Engineer Resume Skills for 2023

- Process Engineering

- Lean Manufacturing Principles

- Six Sigma Methodology

- Production Planning

- Quality Control and Assurance

- Manufacturing Process Optimization

- CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing)

- Product Design for Manufacturability (DFM)

- Continuous Improvement

- Root Cause Analysis

- Material Selection and Sourcing

- Design for Assembly (DFA)

- CNC Programming and Machining

- Industrial Automation

- Robotics Integration

- Manufacturing Process Validation

- Supply Chain Management

- Cost Reduction Strategies

- Value Stream Mapping

- Kanban and JIT (Just-In-Time) Manufacturing

- Equipment Maintenance and Optimization

- Statistical Process Control (SPC)

- Process Documentation

- Standard Operating Procedures (SOPs)

- CAD Software (e.g., AutoCAD, SolidWorks)

- Material Flow Analysis

- Tooling and Fixture Design

- Process Simulation

- Workstation Design and Layout

- Material Handling Systems

- Manufacturing Equipment Selection

- GMP (Good Manufacturing Practice) Compliance

- Quality Management Systems (e.g., ISO 9001)

- Environmental Health and Safety (EHS)

- Regulatory Compliance

- Failure Mode and Effects Analysis (FMEA)

- Design of Experiments (DOE)

- 3D Printing and Additive Manufacturing

- Metal Fabrication Techniques

- Injection Molding

- Supplier Management

- Cost-Benefit Analysis

- Production Capacity Planning

- Waste Reduction (Waste Elimination)

- Process Validation Testing

- CAD Modeling and Simulation

- Assembly Line Design

- Project Management

- CAD/CAM Software Proficiency

- Industry-Specific Manufacturing Knowledge

How Long Should my Manufacturing Engineer Resume be?

Your Manufacturing Engineer resume length should be less than one or two pages maximum. Unless you have more than 25 years of experience, any resume that’s more than two pages would appear to be too long and risk getting rejected.

On an average, for Manufacturing Engineer, we see most resumes have a length of 2. And, that’s why we advise you to keep the resume length appropriate to not get rejected.

Copyright ©2025 Workstory Inc.