Production CV Examples

Start creating your CV in minutes by using our 21 customizable templates or view one of our handpicked Production examples.

Join over 260,000 professionals using our Production examples with VisualCV. Sign up to choose your template, import example content, and customize your content to stand out in your next job search.

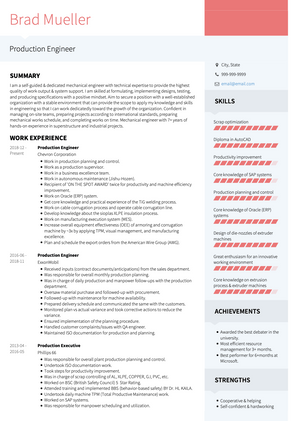

Production Engineer

SUMMARY

I am a self-guided & dedicated mechanical engineer with technical expertise to provide the highest quality of work output & system support. I am skilled at formulating, implementing designs, testing, and producing specifications with a positive mindset. Aim to secure a position with a well-established organization with a stable environment that can provide the scope to apply my knowledge and skills in engineering so that I can work dedicatedly toward the growth of the organization. Confident in managing on-site teams, preparing projects according to international standards, preparing mechanical works schedule, and completing works on time. Mechanical engineer with 7+ years of hands-on experience in superstructure and industrial projects.

WORK EXPERIENCE

Production Engineer

Chevron Corporation

- Work in production planning and control.

- Work as a production supervisor.

- Work in a business excellence team.

- Work in autonomous maintenance (Jishu-Hozen).

- Recipient of 'ON THE SPOT AWARD' twice for productivity and machine efficiency improvement.

- Work on Oracle (ERP) system.

- Get core knowledge and practical experience of the TiG welding process.

- Work on cable corrugation process and operate cable corrugation line.

- Develop knowledge about the sioplas XLPE insulation process.

- Work on manufacturing execution system (MES).

- Increase overall equipment effectiveness (OEE) of armoring and corrugation machine by ~3x by applying TPM, visual management, and manufacturing excellence.

- Plan and schedule the export orders from the American Wire Group (AWG).

Production Engineer

ExxonMobil

- Received inputs (contract documents/anticipations) from the sales department.

- Was responsible for overall monthly production planning.

- Was in charge of daily production and manpower follow-ups with the production department.

- Oversaw material purchase and followed-up with procurement.

- Followed-up with maintenance for machine availability.

- Prepared delivery schedule and communicated the same with the customers.

- Monitored plan vs actual variance and took corrective actions to reduce the variance.

- Ensured implementation of the planning procedure.

- Handled customer complaints/issues with QA engineer.

- Maintained ISO documentation for production and planning.

Production Executive

Phillips 66

- Was responsible for overall plant production planning and control.

- Undertook ISO documentation work.

- Took steps for productivity improvement.

- Was in charge of scrap controlling of AL, XLPE, COPPER, G.I, PVC, etc.

- Worked on BSC (British Safety Council) 5 Star Rating.

- Attended training and implemented BBS (behavior-based safety) BY Dr. HL KAILA.

- Undertook daily machine TPM (Total Productive Maintenance) work.

- Worked on SAP systems.

- Was responsible for manpower scheduling and utilization.

- Worked on 5S implementation.

EDUCATION

Master of Science in Mechanical Engineering

Purdue University

- Production engineering, engineering materials, fluid dynamics, mechanics, product development, and so on.

Bachelor of Science in Mechanical Engineering

Georgia Institute of Technology

SKILLS

- Scrap optimization

- Diploma in AutoCAD

- Productivity improvement

- Core knowledge of SAP systems

- Production planning and control

- Core knowledge of Oracle (ERP) systems

- Design of die-nozzles of extruder machines

- Great enthusiasm for an innovative working environment

- Core knowledge on extrusion process & extruder machines

ACHIEVEMENTS

- Awarded the best debater in the university.

- Most efficient resource management for 3+ months.

- Best performer for 6+months at Microsoft.

STRENGTHS

- Cooperative & helping

- Self-confident & hardworking

- Flexible with working conditions

- Good command over languages & communication skills

Copyright ©2025 Workstory Inc.